15 August 2025 news

A new study presents a comprehensive risk assessment of 21 land-based fish farms in Norway using a standardized risk assessment methodology developed by Akvaplan-niva. The farms assessed vary in age, technology type and production scale. The focus of the assessments has been on technical and operational risk factors that can affect fish mortality. The results show no clear relationship between system complexity and overall risk. Instead, effective design, good operating procedures and built-in safety margins were key factors in reducing risk.

Background

In recent years, the aquaculture industry in Norway has faced challenges related to adverse events and mortality in land-based systems for salmon farming. These events, which mainly occur in land-based smolt facilities, but are also expected in facilities for larger salmon, raise serious concerns about fish welfare. The events can also lead to high mortality and significant economic losses for the aquaculture industry.

To address these challenges, the aquaculture industry is focusing on risk mitigation measures such as improved system design to avoid stagnant water and particle sedimentation areas. The industry actors also focus on reducing the gap between planned and achievable production. Technical assessments and risk evaluation are crucial, not only for efficient operations and fish welfare, but also to secure values and enable insurance of industry investments.

The insurance sector has great interest in this area, as both the facilities and the biomass represent high value. The Norwegian insurance company Gjensidige, which owns and is responsible for the study, has contributed significantly by sharing a comprehensive dataset from risk assessments of 21 land-based aquaculture facilities that have been assessed using a common standardized method developed by Akvaplan-niva in collaboration with NIVA.

The aim of the assessment and the subsequent analysis is to reduce fish mortality, improve fish welfare and mitigate economic risk. The goal of the project is to contribute to a more robust and sustainable land-based aquaculture industry through increased awareness among fish farmers about the potential hazards and through empowering them in taking risk-reducing action.

The method

This study is based on 21 risk assessments of different land-based aquaculture facilities in Norway, including 18 smolt and post-smolt facilities for Atlantic salmon (Salmo salar), one salmon hatchery, one smolt facility for rainbow trout (Oncorhynchus mykiss) and one juvenile facility for lumpfish (Cyclopterus lumpus).

The facilities varied in age from the early 1980s to the newest one completed in 2022. In terms of production capacity, the annual biomass output ranged from 220 tons to 3,500 tons. The plants represented various technology types including FTS, HYB, and RAS systems, incorporating both Moving Bed Biofilm Reactor (MBBR) and Fixed Bed Biofilm Reactor (FBBR). MBBR systems are a type of biological wastewater treatment used in aquaculture to improve water quality and create a more stable environment for fish. FBBR is a biological water treatment system where beneficial bacteria grow on a fixed media, creating a biofilm that removes waste products from the water.

The facilities were risk-assessed according to a standardized protocol and risk matrix. All evaluations were conducted by the same team of evaluators, providing a basis for comparison of land-based aquaculture facilities in Norway.

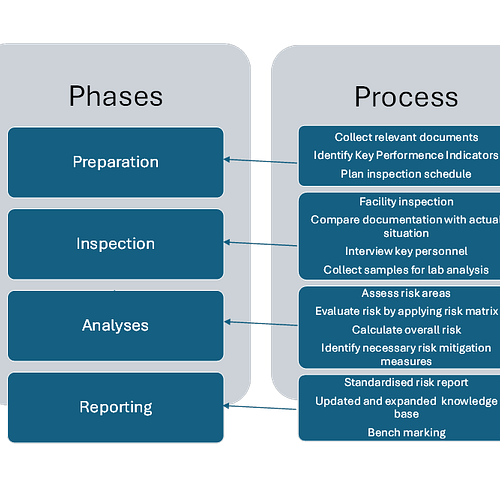

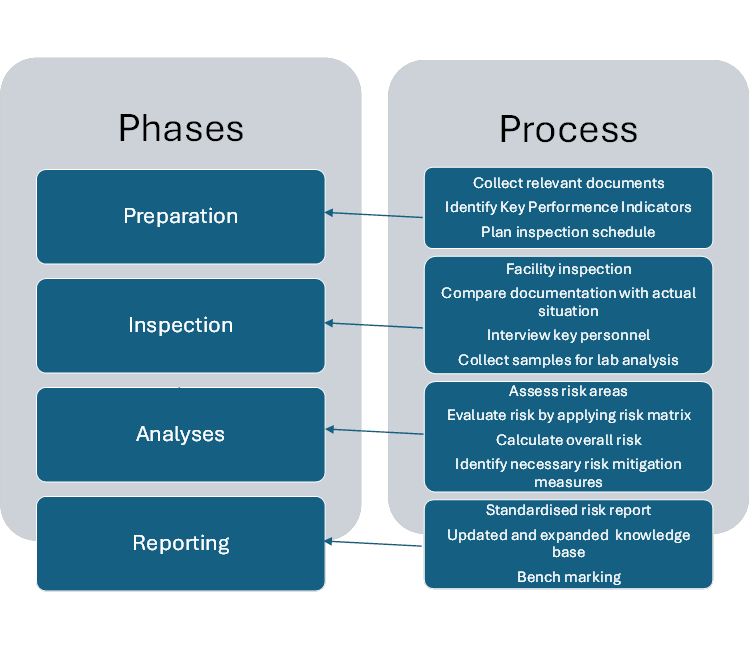

The risk assessments were limited to evaluation of fish mortality as the ultimate consequence. Risks that may affect e.g. disease, escape, and fire were not included in the assessments, although these can also impact fish welfare and lead to fish mortality. The method is summarized in Figure 1.

Figure 1: Flowchart for the risk assessment method based on the principles of the Akvaplan-niva procedure

Results

The assessments of 21 land-based facilities, with different sizes, technologies and water treatment intensity, showed no clear relationship between increased complexity, degree of water recycling or specific system types and higher overall risk. The system types that were evaluated was Flow-Through System (FTS), Hybrid flow-through system (HYB) and Recirculating Aquaculture Systems (RAS). Although advanced systems such as RAS often entailed greater operational complexity, both low and high-risk values were observed in all types of facilities. The two highest and two lowest total values were all found among facilities using RAS or FTS+RAS, demonstrating that effective risk management is possible even in very complex systems.

The relatively high proportion of medium risk values among FTS facilities may be due to fewer departments, where individual factors have a greater impact on the overall assessment. RAS facilities were more often associated with deviations in water quality, often associated with the accumulation of nitrogen compounds and metals – conditions expected in recirculation systems. Low risk levels in some RAS facilities were associated with solid design, good treatment capacity and strong operating procedures.

The project team concludes that system robustness depends on both design and operation. FTS systems, which often use gravity-fed inlet water, are less vulnerable to power outages. RAS, with minimal use of inlet water, are less exposed to external water quality issues, but more prone to internal failures. Mechanical failures, sensor failures, or power outages can quickly escalate due to the integrated nature of the system.

Most facilities had good redundancy and backup solutions for critical resources such as water, oxygen and electricity. Personnel at the facilities with longer operating times generally showed greater awareness and had, with time, improved their routines. Increased risk was typically during the start-up phase, when introducing new technology or when changing production strategy – phases that require time to understand the systems and improve the design.

Risk factors related to water chemistry were more crucial for overall risk in RAS than in FTS/HYB, due to increased complexity in water treatment and accumulation of certain substances. Risk of H₂S production was higher in RAS and increased with more use of seawater, but the results show that this risk can be reduced with good water treatment, precise measurement and established routines – several seawater RAS had no problems with H₂S.

Several mortality cases where H₂S was suspected as the cause occurred in plants with MBBR systems, where design and mixing problems led to particle accumulation. This points to challenges associated with MBBR design and operation. However, it is often difficult to draw firm conclusions in such incidents, as the suspicion of H₂S usually arises by excluding other causes. The assessments are often supported by the absence of other abnormalities and a typical acute mortality pattern without obvious clinical symptoms.

In addition, there is a need for increased awareness of the use of chemicals. Chemicals were often used to solve acute problems such as particle accumulation or foaming, but the consequences of such use were not always adequately assessed. Chemical treatment may provide short-term effects, but addressing the underlying causes – such as improving particle removal or using physical foam control – is more sustainable and effective.

The findings highlight the importance of robust system design, informed operational practices and continuous monitoring to ensure good fish welfare and reduce economic losses in land-based aquaculture.

Facts about the RM Akva project:

Scope: The project included risk assessments of 21 land-based fish farms in Norway, including salmon, rainbow trout and crayfish farms, carried out by Akvaplan-niva and NIVA on behalf of Gjensidige Forsikring.

Method: All assessments were carried out according to a standardized method developed by Akvaplan-niva.

Purpose: The aim was to reduce mortality, improve fish welfare and strengthen the insurance basis through better risk management.

Main findings: Complexity in the systems (e.g. RAS) does not automatically entail higher risk – good design and routines are most important.

Actor: The project was financed by Gjensidige Forsikring, which also contributed extensively with risk assessment data to the project team.

The project team: Sondre Veberg Larsen, Thor Magne Jonassen, Endre Steigum, Ole-Kristian Hess-Erga, Heidi Stuve, Bård Worum, Jonny Nikolaisen, Sondre Kvalsvik Stenberg, Stine Egeland

The results from this study will be presented on different events during the Aqua Nor fair in Trondheim:

- Wednesday August 20th, 09.30 - 10.30 in a seminar led by the insurance company Gjensidige in the meeting room is "Munkholmen". It will be possible to ask questions to the study during the seminar.

- Wednesday 20th, 15.20 - 15.45, in the science session "New production concepts and engineering challenges for marine aquaculture 2050." This session is led by Xinxin Wang from Akvaplan-niva. Meeting room "Mendelsohn".

- Thursday August 21th, 10.30 -11.30, at the Aqua Nor Research Plaza (Forskningstorget)